There are various types of injection molding processes. Two-color or two-shot injection molding is one of them. With this type of injection molding process, you will need to use the two-color injection molding machine to get it done. So, what is a two-color injection molding machine?

In this guide, you will learn about the two-color injection molding machine, along with its advantages and limitations.

Two-Color Injection Molding Machine – What is It?

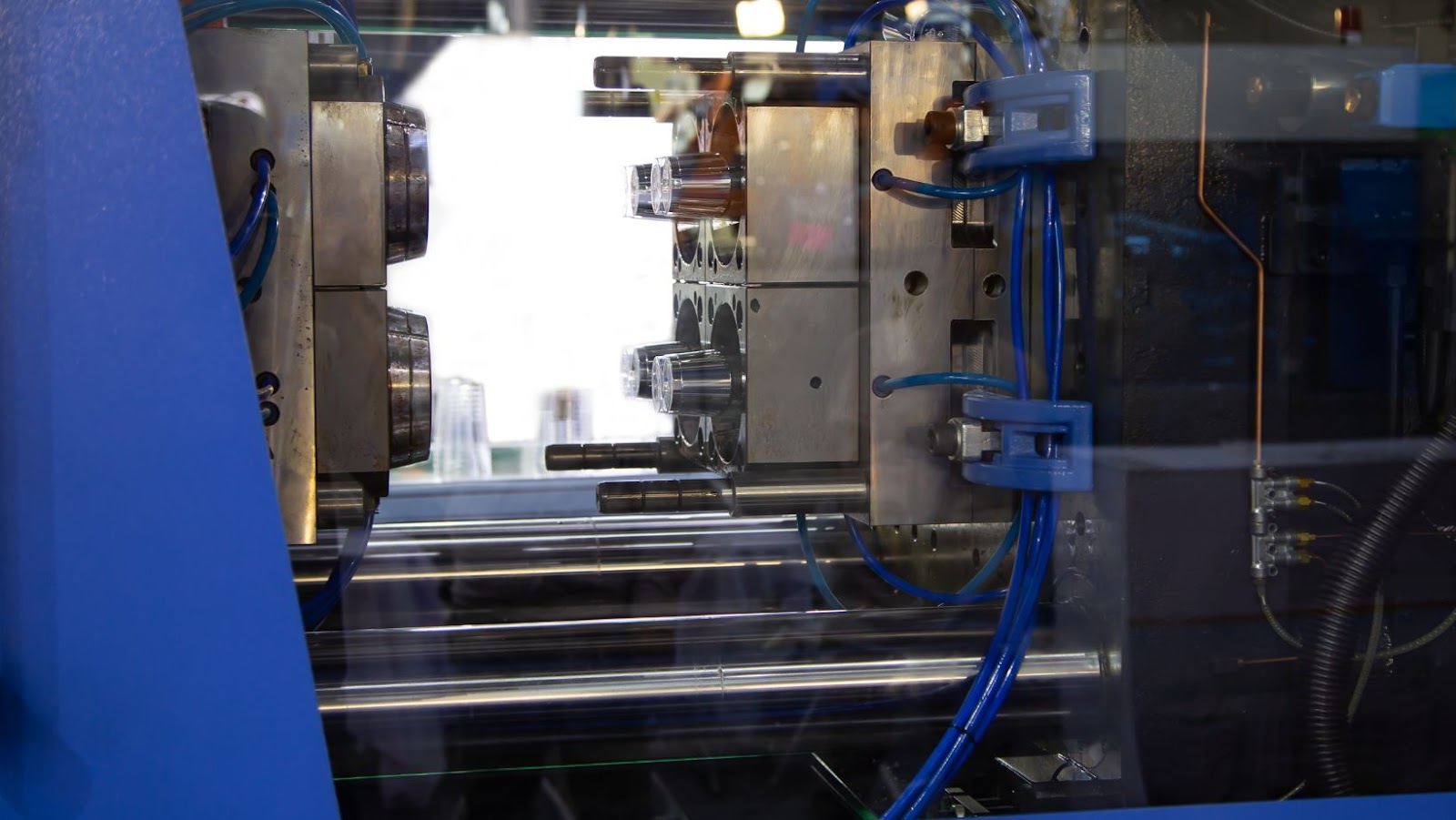

Two-color injection molding machine is a special plastic molding equipment designed to perform the two-color or two-shot injection molding process. This equipment will allow you to use two different materials of two different colors and process them in the same mold to create a distinct injection-molded product. With this equipment, you can also use a computer program to assist with the two-color injection molding operations.

Common Features of a Two-Color Injection Molding Machine

The two-color injection molding machine differs in some aspects when you compare it with the regular injection molding equipment. Here are some common features of a two-color injection molding machine:

● Facilitating the two-color injection molding process. The two-color injection molding machine will allow you to perform the two-color injection molding process, which is its primary purpose. With the same mold, you can add two different colors or materials and combine them together to create a product that has two color variations in it.

● Easy material application. The two-color injection molding machine will allow you to apply different materials of different colors with no complicated steps. There are containers for you to put different materials of different colors within the equipment, which will then get processed in the same mold later.

● A wide range of material options and color variations. With the two-color injection molding machine, you can use various materials and various color variations to create different variations of your products. This is in contrast to the regular injection molding machine that will only allow you to use one material at a time.

● Simple and easy to maintain. It is also simple and easy for you to use and maintain the two-color injection molding machine. You just need to follow some simple steps to activate and use the machine. You can also perform some maintenance work from time to time to ensure that your machine will work well all the time.

● Operator safety. The two-color injection molding machine will also provide you with various safety features for the operators. The mechanical and hydraulic system of the two-color injection molding machine will operate within the safety range of the operators, and the operators can also control the injection molding process at any time.

● Computer-assisted operations. Also, with the two-color injection molding machine, you don’t need to do everything manually. You can program the machine using computer-assisted programming to oversee the manufacturing process or customize it based on your project requirements.

Benefits of Two-Color Injection Molding Process

Two-color injection molding can provide you with plenty of benefits when compared to the regular injection molding process. Here are the benefits of the two-color injection molding process:

● Improved product aesthetics. By using two color variations, you can create various injection-molded products that offer better aesthetics than regular injection-molded products. With better aesthetics, you can attract the interest of more people to buy your products in the market.

● Hard and soft material combinations. You can also combine the hard and soft materials in one injection-molded product. So, you can figure out which combinations are best on a per-case basis, whether you need to combine soft-soft, hard-hard, or hard-soft materials in your product.

● Better product ergonomics. In some products, you can also combine different materials to create better product ergonomics. For instance, when creating a screwdriver, you can add rubbery materials to help add the ergonomic factor to the screwdriver while you use it.

● Durable material bonding. The two-color injection molding allows you to create a durable and strong material bonding for your injection-molded products. So, this process will ensure that all materials will have a strong bond, which you can’t separate during regular use.

● Create a better sealing for the products. For products that need some kind of sealing, such as cases or containers, you can use two-color injection molding to create a better sealing for them. You can use the silicone rubber molding to do this.

Are There Limitations in the Two-Color Injection Molding Machine?

Despite the capabilities that a two-color injection molding machine can provide to you, there are also some limitations for this equipment that you need to know. Here are some limitations of the two-color injection molding machine:

● Material compatibility factor. With the two-shot injection molding process, you will need both materials to be compatible with each other so that they can be molded into the same mold in this process. So, you can’t just pick any random plastic materials for this process, as you will also need to think about the material compatibility factor.

● Design limitations. You also have some design limitations with the two-shot injection molding. You can’t create a design blueprint that has too many geometrical complexities in it, as the equipment might not be able to process it.

● Double injection molding cycles. The two-shot injection molding machine will also perform the injection molding process in more cycles when compared to the regular injection molding process. The equipment needs to use double or even more injection molding cycles just to complete the injection molding process of a single product.

● More expensive investment. Because of its features and the two-shot injection molding capability, the two-color injection molding machine will be much more expensive for you to purchase. Also, you will need to use two different materials in each injection molding process, which means a more expensive injection molding cost for you.

Conclusion

The two-shot injection molding machine can help you create various injection-molded products with different materials and color variations in them. The process is similar to the regular injection molding process, with the difference being that you will need to perform the injection molding process two times in the same mold. It is also important to understand that the two-color injection molding equipment has its own benefits and limitations.