HPC, or high-performance computing, is a vital technology that helps the automotive industry innovate and succeed. It allows carmakers to design new vehicles faster and more efficiently while reducing costs.

By understanding how HPC works and the benefits it provides, businesses can better assess its potential for their own needs. In this article, we will discuss what HPC is, how it aids automakers, and some of the challenges associated with its implementation.

What is HPC, and Why is it Essential for the Automotive Industry?

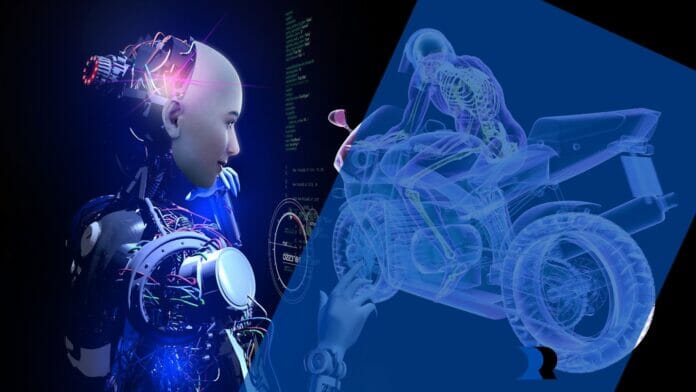

By definition, HPC uses computers or clusters to solve complex computational problems. It enables companies to process data and perform calculations much faster than traditional or single-computer systems. It makes it possible for automotive engineers to develop new models quickly and efficiently and make improvements to existing ones in a shorter period.

HPC also helps reduce costs by eliminating the need for expensive trial-and-error testing that can slow down the pace of innovation. Using large amounts of data from various sources, carmakers can simulate how their designs will perform under real-world conditions before they even build prototypes. It saves money on materials, workforce, and other associated costs while allowing them to produce better vehicles more quickly.

How Does HPC Help Automakers Design and Test New Vehicles?

HPC helps automotive engineers generate 3D models of new cars. Through simulations, they can accurately predict how the vehicle will drive, handle and perform under different conditions. Automakers can use HPC to simulate tests for crashworthiness, navigation systems, engine performance, and other aspects of a car’s functionality to ensure that their designs meet safety standards and customer expectations before production begins.

In addition, automakers can also use HPC to speed up the development process by testing multiple design iterations at once. By running large-scale simulations and quickly analyzing data from real-world tests, they can identify potential problems earlier in the process while simultaneously evaluating various solutions. It allows them to produce more advanced vehicles in a fraction of the time required with traditional methods.

Despite its clear advantages, implementing HPC can be complicated and costly for automakers. It requires a significant investment in hardware, software, and personnel to ensure that their systems run smoothly and effectively. Additionally, technicians must be trained to use the technology properly to achieve optimal results.

The Benefits of Using HPC in the Automotive Industry

Despite the challenges associated with its implementation, HPC provides automakers with numerous advantages. It enables them to develop higher-quality vehicles more quickly and cost-effectively while ensuring they meet safety standards and customer expectations. The technology is also increasingly used in autonomous driving systems, helping cars become more innovative and self-sufficient.

Moreover, HPC helps automotive companies streamline their processes by allowing them to digitize data from various sources and use it for predictive analytics. It leads to improved products and a better understanding of customer behavior, which can use for marketing purposes and informed decision-making. Finally, HPC allows quicker prototyping so carmakers can bring their designs to market faster than ever.

Case Studies of How HPC Has Been Used in the Automotive Industry

HPC has been used in the automotive industry for years, with several case studies illustrating its effectiveness.

For example, BMW has implemented HPC to develop powertrains and other components in their cars. By using large-scale simulations and analysis tools, they have dramatically reduced design time while increasing efficiency.

Additionally, Mercedes-Benz uses HPC as part of its autonomous driving system development process. Through detailed simulations and analytics, they can evaluate how their self-driving vehicles perform under different scenarios and road conditions to ensure that they are safe and reliable before production begins.

Toyota is another automaker that relies on HPC for various applications. The company is using the technology to develop new fuel-efficient engines, improve its manufacturing process and optimize its supply chain operations.

The Future of HPC and the Automotive Industry

HPC is rapidly becoming an essential tool for automotive engineers and companies. As automakers continue to explore new ways to use the technology, we can expect to see even more advanced vehicles with increased safety, efficiency, and performance. Additionally, HPC will help carmakers optimize their production processes while simultaneously allowing them to develop more cost-effective solutions.

While implementing HPC comes with its own set of challenges, it is clear that the benefits far outweigh the costs of designing more innovative cars. With advancements in computing power and analytics tools, we can look forward to a future full of exciting possibilities for HPC automotive and other industries.

In Conclusion

HPC is a vital part of the automotive industry’s future. It offers automakers many advantages, such as faster development times, improved efficiency, predictive analytics, and cost savings. As HPC technology continues to evolve and become more widely adopted, we can expect to see even more significant advancements in car design and performance that will benefit both consumers and the automotive industry alike.