Think of a simple, everyday tool: a straw. When you suck on it, you pull liquid up and out of a cup. Now, imagine a straw that can handle much more demanding jobs, like moving thick paint, chemicals, or even food. That’s the basic idea behind a diaphragm pump.

Instead of your lungs, it uses a flexible disc that moves back and forth. This motion pushes and pulls liquids and gases through the pump, making it incredibly versatile. These pumps are quiet, reliable workhorses, and they’re used in more places than you might think.

Let’s look at how they work and why they’re so helpful:

Understanding How a Diaphragm Pump Works

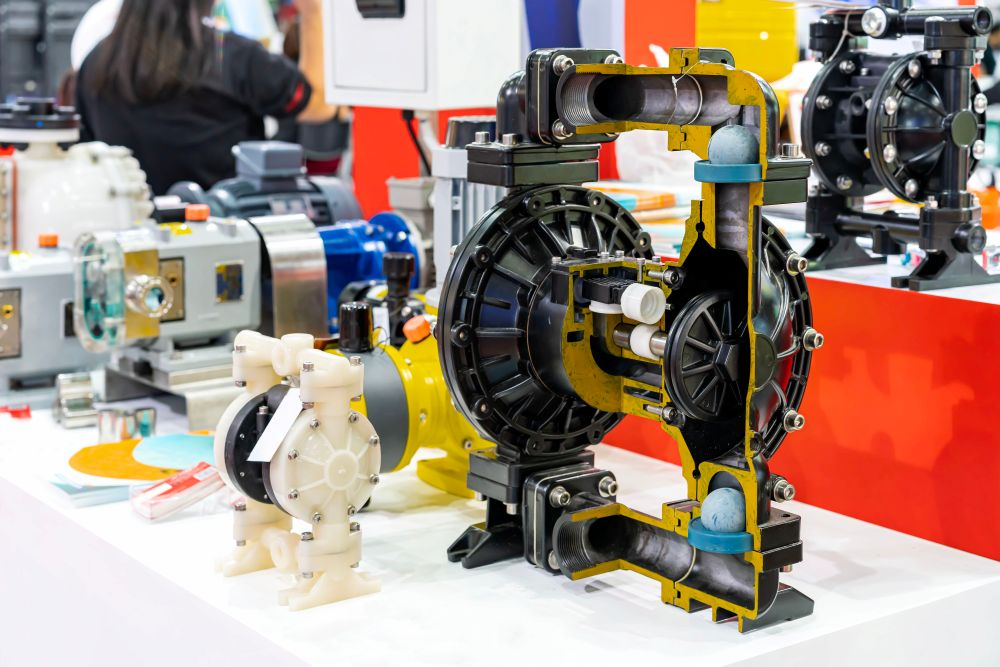

A diaphragm or membrane pump is a type of positive-displacement pump. It moves fluid using a flexible diaphragm and check valves that control the direction of flow. When the diaphragm moves backward, it creates suction that draws liquid into a suction manifold. As it moves forward, it pushes that liquid out through a discharge valve. This reciprocating action keeps the flow consistent and smooth.

Many high-quality models are designed for precision work, especially in labs or medical processes. They can handle liquids and gases, making them ideal for vacuum applications and gentle fluid transfer. Because the fluid never touches the internal pump parts, contamination is less likely, which can be valuable in sterile environments.

Some designs use air pressure to move the diaphragm, which are called pneumatic pumps. Others rely on an electric motor, known as electric diaphragm pumps, which can provide more control over the flow rate. Depending on the setup, a diaphragm pump can also function as a single-acting or double-acting pump, meaning it can move fluid in one or both strokes of the diaphragm.

When looking for options, do your research to find a model that fits your specific needs. The good thing is that there are many resources available online. For instance, you can visit knf.com/en/global to learn more about the available types. Make sure you choose a diaphragm pump that matches the type of fluid you’ll be handling and the pressure and flow rate your system requires.

5 Benefits of Using a Diaphragm Pump

A diaphragm pump offers several practical advantages that make it a reliable choice for handling different fluids. Here are a few:

1. Handles a wide range of fluids

A diaphragm pump can handle almost any fluid texture, from watery solutions to thick slurries. Because of its pressure capabilities, it can manage liquids with particles, corrosive chemicals, or even viscous materials. That’s one reason they’re used in chemical pumping, water treatment, and food processing.

2. Maintains a leak-free and contamination-resistant design

The pumping chamber is sealed off, which means leaks are less likely. The diaphragm separates the fluid from other internal pump parts, reducing contamination risks. This design can be crucial when dealing with sterile products, toxic materials, or chemicals used in sensitive pumping systems.

3. Offers self-priming capability

A key advantage of a membrane pump is that it can self-prime, meaning it doesn’t need to be manually filled with liquid before use. This makes setup quicker and reduces downtime in systems that rely on fluid transfer.

4. Operates dry without damage

While many pumps require fluid for lubrication or cooling, diaphragm pumps can run dry for short periods without harm. This adds flexibility, especially in operations where liquid flow may temporarily stop or when air enters the line.

5. Supports safe transfer of hazardous or sensitive fluids

Because the diaphragm acts as a barrier, hazardous or sensitive materials stay contained. This is why diaphragm pumps can be found in industries that handle reactive chemicals or delicate biological fluids. They can maintain controlled flow even when conditions vary.

5 Uses of Diaphragm Pumps

Diaphragm pumps are used across many industries because they can handle a wide range of fluids safely and efficiently. Some of them include:

1. Water and wastewater treatment

In water treatment plants, diaphragm pumps can accurately dose chemicals like chlorine and lime. Their check valves keep the flow stable, and their ability to handle corrosive fluids can make them dependable for chemical dosing and sludge handling.

2. Food and beverage production

These pumps are widely used for transferring syrups, sauces, and flavorings. Their smooth pumping action helps preserve texture and taste, while their sealed chambers protect food from contamination. The inclusion of shut-off valves in the system can make cleaning and maintenance easier between batches.

3. Pharmaceutical and cosmetic manufacturing

Diaphragm pumps are essential in medical processes and pharmaceutical manufacturing. They can move gels, creams, and solutions without exposing them to air or outside contaminants. Their controlled flow rate ensures precision, making them ideal for sterile production lines.

4. Chemical processing

Diaphragm pumps can handle aggressive fluids like acids and solvents in chemical processing. Their resistance to corrosion and strong pressure capabilities make them suitable for safely transferring hazardous liquids. They can also support vacuum applications, where a rough vacuum is needed to move volatile substances.

5. Oil and gas operations

Diaphragm pumps are used in various oil and gas operations, from transferring drilling fluids to managing waste and fuel. Their chemical resistance and strength can help ensure reliable fluid movement in demanding conditions.

Conclusion

The diaphragm pump is a reliable machine for moving liquids. Its ingenious sealed design uses a flexible membrane to push and pull fluids, preventing leaks and contamination. This combination of power and precision makes it a workhorse in diverse industries, from handling harsh chemicals to processing food. It’s a simple, low-maintenance solution for nearly any demanding fluid transfer job.