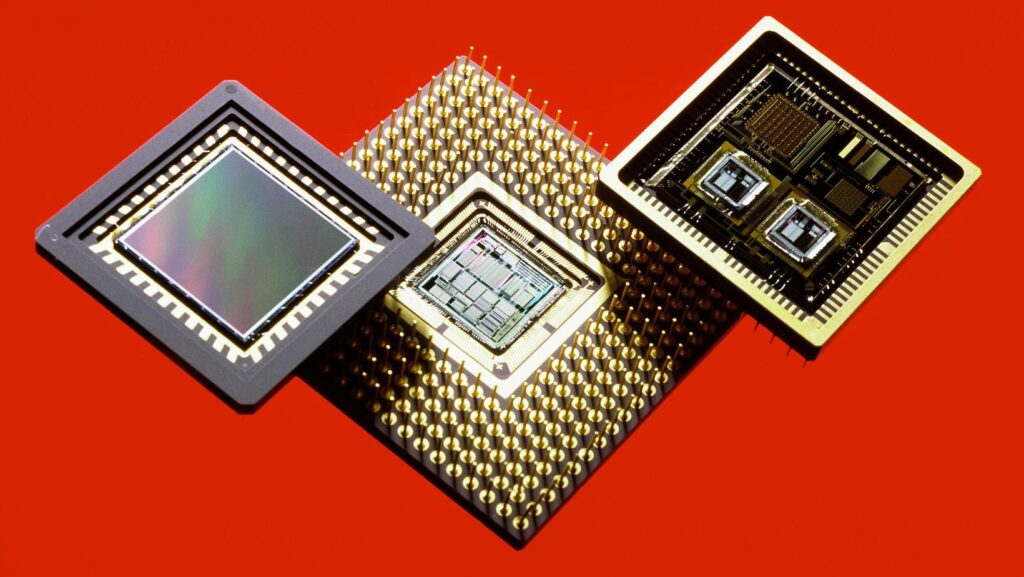

The beating heart of the world of current electronics is microchips, whether it is a smartphone or a satellite. They are highly advanced in terms of technology, but at the same time, physically fragile, particularly when exposed to elements of the environment like water.

The following packaging strategies represent guidelines on the pristine ways of protecting the microchips in the light of moisture-induced damage during shipment and storage.

The Risks of Moisture Exposure

Humidity in custom electronics packaging may destroy microchips in several ways:

- Corrosion of Metal Contacts: Humid conditions may cause exposed copper or gold contacts to oxidise and disrupt conductivity.

- Popcorning during Reflow Soldering: Moisture contained in packaging materials or the chip itself can easily boil off in a heated, high-temperature solder process and produce delamination or cracking.

- Electrochemical Migration: Moisture will form unwanted conduction paths between neighboring conductors, and when conductors are nearby, a short will occur under the influence of voltage.

- Shorter shelf life: Diminished exposure to moisture with time, even in storage, can weaken the reliability of the component before it is mounted.

These hazards indicate that moisture barrier controls are required to cover the manufacturing floor to the ultimate point of use.

Packaging Strategies to Prevent Moisture Damage

The packaging system forms the first and most crucial set of moisture protection. Moisture-sensitive device (MSD) handling guidelines exist in the electronics logistics industry, and by adhering to these, the protection will be consistent.

Important packaging strategies are:

- Moisture Barrier Bags (MBBs): Multiple-layer laminates are used in developing these bags, this has proved an extremely effective barrier against moisture and oxygen.

- Desiccant Packs: Desiccant Packs are put inside MBBs, and they dry up any excessive moisture and hinder the formation of humidity.

- Humidity Indicator Cards (HICs): They are cards that turn color in response to unsafe moisture exposures that prove to the eye package integrity.

- Vacuum Sealing: Eliminates air and reduces moisture penetration in the course of long journeys.

- Double Packaging: It provides unnecessary redundancy of wrapping inner protective packages into further moisture-impervious covers, which can be exploited in extreme environments.

To obtain the best outcomes, packaging material needs to be tested and verified to guarantee its moisture vapor transmission rates (MVTR) are adequate to be protective or above.

Climate-Controlled Shipping Solutions

Packaging can give localized protection, but the shipping environment itself can protect or jeopardize the integrity of the microchips. The following are best practices in climate-controlled shipping:

- Humidity and Temperature Control: The specialized vehicles and containers with HVAC units have conditions within the recommended ranges of the manufacturer.

- Active/Passive Control: Active systems have the use of powered climate controls, whereas passive systems rely on insulation and preconditioned materials. Passive is chosen should the need to ship a sensitive item over a long period.

- Sealed Containers: The contact with the surrounding humidity can be eliminated during loading and unloading.

- Route Planning: Whenever possible, do not use routes or transit through areas of high humidity or during monsoon seasons.

A multi-layer defense climate control, plus proper packaging, such as that from Utz, can be used, particularly on high-value or ultra-sensitive shipments of microchips.

Handling and Storage Best Practices

60% of businesses suffered damages or losses when dealing with non-traditional courier methods. Moisture protection does not end when the products arrive at their packaging and shipping stage; the importance of handling and storage is equally emphasized to retain the levels of integrity. Careful work in packaging is easily counteracted by even a short exposure to environments that have not been regulated.

Handling and storage practices to be considered include:

- Controlled Storage Areas

- Minimized Exposure Time

- Correct Restoration

- Staff Training

- FIFO inventory management:

An ordinary practice on manufacturing sales floors is the use of dry bake ovens to dry off absorbed moisture and then store in situations where storage conditions are sub-optimal.

Monitoring and Quality Assurance

The last line of defence for storage of microchips will be constant checking and quality controls to ensure that moisture levels will not exceed safe levels anywhere along the supply chain.

Monitoring and QA practices recommended are:

- Data Loggers: Install humidity and temperature sensors in shipping containers to gauge real-time data in the environment.

- Periodic Package Inspections: Do a physical inspection of HICs as received and at pre-determined intervals in storage.

- Incoming Quality Control (IQC): Sample in transit shipments by conducting capacitance or weight-gain measurements on random samples of the shipment to check moisture ingress.

- Audits of Compliance: Audit supplier and logistics partner processes on a regular basis to verify that they are complying with packaging and handling specifications.

- Root Cause Analysis: Investigate all cases of moisture-related failure where improvements to preventative measures may be needed.

Through systematic monitoring, the companies can notice the deviations and correct them before they translate to failures in the field, which are costly.

In Conclusion

The issue of ensuring that microchips are not exposed to moisture during transit has many aspects to it that cannot be simply addressed by putting components in bags. It entails well-coordinated practices comprising strong packaging, transportation cooled by climate control, disciplined handling functions, and watchful attention.

Manufacturers and distributors can minimize the likelihood of corrosion, popcorning, and other such moisture-related failures by using industry-standard specifications and by taking advantage of new technologies in advanced moisture barriers, coupled with high environmental control in all supply chain processes.

Finally, the correct storage of microchips against humidity is not merely an issue of protecting the components but also the performance, reliability, and reputation of the products that they drive.