If you’re looking for a creative and witty way to earn money, look no further than 3d printing. With this technology, you can create just about anything you can imagine, and people are always looking for new and innovative things to print. Whether you’re looking to start your own 3d printing business or just want to make some extra money on the side, there are plenty of ways to do it. In this blog post, we’ll show you how to make money 3d printing, so you can start earning cash today.

What is 3D printing?

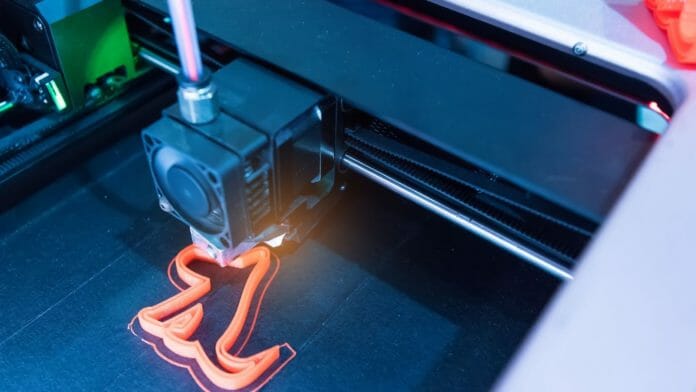

3D printing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the entire object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

3D printing is the opposite of subtractive manufacturing which involves taking away material by drilling, milling, or cutting.

How to make 3D printing

There are a few different ways to make money from 3D printing. Below are three popular methods:

1. Sell your 3D models

If you have some creative flair and fancy yourself as a bit of a designer, then one way you can make money from 3D printing is by selling your 3D models online. There are a number of websites where you can do this, such as Shapeways and TurboSquid. All you need to do is upload your model, set a price, and wait for someone to buy it.

2. Provide a 3D printing service

Another way to make money from 3D printing is to provide a printing service for people who need something printed but don’t have their own printer. This is a great option if you have a reliable and high-quality printer that others can use. You can advertise your services online or in local classifieds, and set your own prices.

3. Sell products made with 3D printing

If you’re not into design but still want to cash in on the 3D printing phenomenon, then another option is to sell products that are made using 3D printers. This could be anything from artworks to jewelry to phone cases – the sky’s the limit! You can sell these items either via an online store or offline in markets or fairs.

What are the benefits of 3D printing?

3D printing offers a number of benefits over traditional manufacturing methods. It is a more efficient process that often requires less raw material and energy to produce a given product. It also offers more design freedom, since complex shapes and internal features can be easily created with 3D printing. And since 3D printing can be done on-demand, it eliminates the need for large inventories of finished products.

What are the drawbacks of 3D printing?

3D printing has many applications, but there are also some significant drawbacks that need to be considered. One of the biggest problems with 3D printing is the high cost of printers and materials. Printers can cost thousands of dollars, and filaments can be expensive as well. In addition, 3D printed objects can often be weak and fragile. They also tend to have a lower resolution than objects made with traditional manufacturing methods.

What are the best 3D printers for making money?

If you’re looking for the best 3D printers for making money, then you’ll want to consider a few factors before making your purchase. The size of the 3D printer, the type of filament it uses, and the price are all important factors to keep in mind.

The best 3D printers for making money are typically those that are larger in size. This is because larger printers can print more items in a shorter amount of time, which means you can make more money in a shorter period of time.

The type of filament that the 3D printer uses is also important to consider. Some filaments are more expensive than others, so if you’re looking to save money, you’ll want to choose a 3D printer that uses a less expensive filament. However, if you’re looking for a higher quality product, then you’ll want to choose a 3D printer that uses a more expensive filament.

Finally, the price of the 3D printer is also an important factor to consider. You’ll want to find a 3D printer that fits within your budget so that you don’t end up spending more money than you need to.

How much money can you make from 3D printing?

3D printing has the potential to be a very profitable business. The key is to find a niche market and offer products that are in high demand. There are a few ways to do this:

1. Sell 3D printed objects online: There are a number of online marketplaces that allow you to sell 3D printed objects, such as Shapeways and Sculpteo. All you need is a 3D printer and an internet connection.

2. Start a 3D printing service: Another option is to start a 3D printing service, which can be done offline or online. This involves setting up a website where customers can upload their designs and order prints. Once the designs are finalized, you will print them out and ship them to the customer.

3. Sell 3D printing services: If you have experience in 3D printing, you can sell your services to businesses or individuals who need help with specific projects. This could involve creating custom designs, prints, or repairs.

What are some common 3D printing applications?

3D printing technology is being used in a variety of industries to create products and components that have traditionally been difficult or impossible to manufacture.

Some common 3D printing applications include:

-Prototyping: Creating prototypes of products or components to test their design and functionality before manufacturing them.

-Customization: Creating customized products or components, such as prosthetic limbs or hearing aids, that are specific to the individual user.

-Manufacturing: Creating finished products or components using 3D printing technology, such as eyeglass frames, medical implants, and automotive parts.

-Construction: Building structures using 3D printed bricks made from concrete or other materials.

What are some common 3D printing materials?

There are a variety of different materials that can be used for 3D printing, but some of the most common include:

ABS plastic: One of the most popular materials for 3D printing, ABS plastic is strong and durable. It can be printed in a wide range of colors and is relatively affordable.

PLA plastic: PLA is another popular choice for 3D printing. It is made from renewable resources, so it is more environmentally friendly than ABS. PLA is also available in a wide range of colors, but it is not as strong as ABS.

Nylon: Nylon is a strong, lightweight material that can be printed in a variety of colors. It is often used for functional parts because it can withstand high temperatures and stress.

Metal: A variety of metals can be used for 3D printing, including aluminum, stainless steel, and titanium. Metal parts are strong and durable, but they can be expensive to print.

What are some common 3D printing technologies?

There are a few different types of 3D printing technology, each with its own advantages and disadvantages. The two most common 3D printing technologies are FDM (Fused Deposition Modeling) and SLA (Stereolithography).

FDM: Fused Deposition Modeling is the most common type of 3D printing technology. It works by melting plastic filament and depositing it in layers to create a 3D object. FDM printers are relatively inexpensive, and the plastic filament is widely available in a variety of colors. However, FDM prints can be weak and brittle, and the printed objects can have visible layer lines.

SLA: Stereolithography is a less common type of 3D printing that uses light-sensitive resin instead of plastic filament. SLA printers are more expensive than FDM printers, but they can produce higher-quality prints with smoother surfaces and finer details.

How do I get started in 3D printing?

There are a few things you need in order to start 3D printing: a 3D model, a 3D printer, and filament. That’s it!

3D models can be created from scratch using a CAD program (Computer Aided Design), or you can download them from the internet. Once you have a model, you need to load it onto your 3D printer.

3D printers come in all shapes and sizes, but they all have one thing in common: they use filament to create 3D objects. Filament is a type of plastic that is melted by the printer and then extruded through a nozzle to create an object layer by layer.

The most important thing to remember when starting out in 3D printing is that it takes time and practice to become proficient. Don’t be discouraged if your first few prints don’t turn out perfectly – it takes most people a while to get the hang of it!